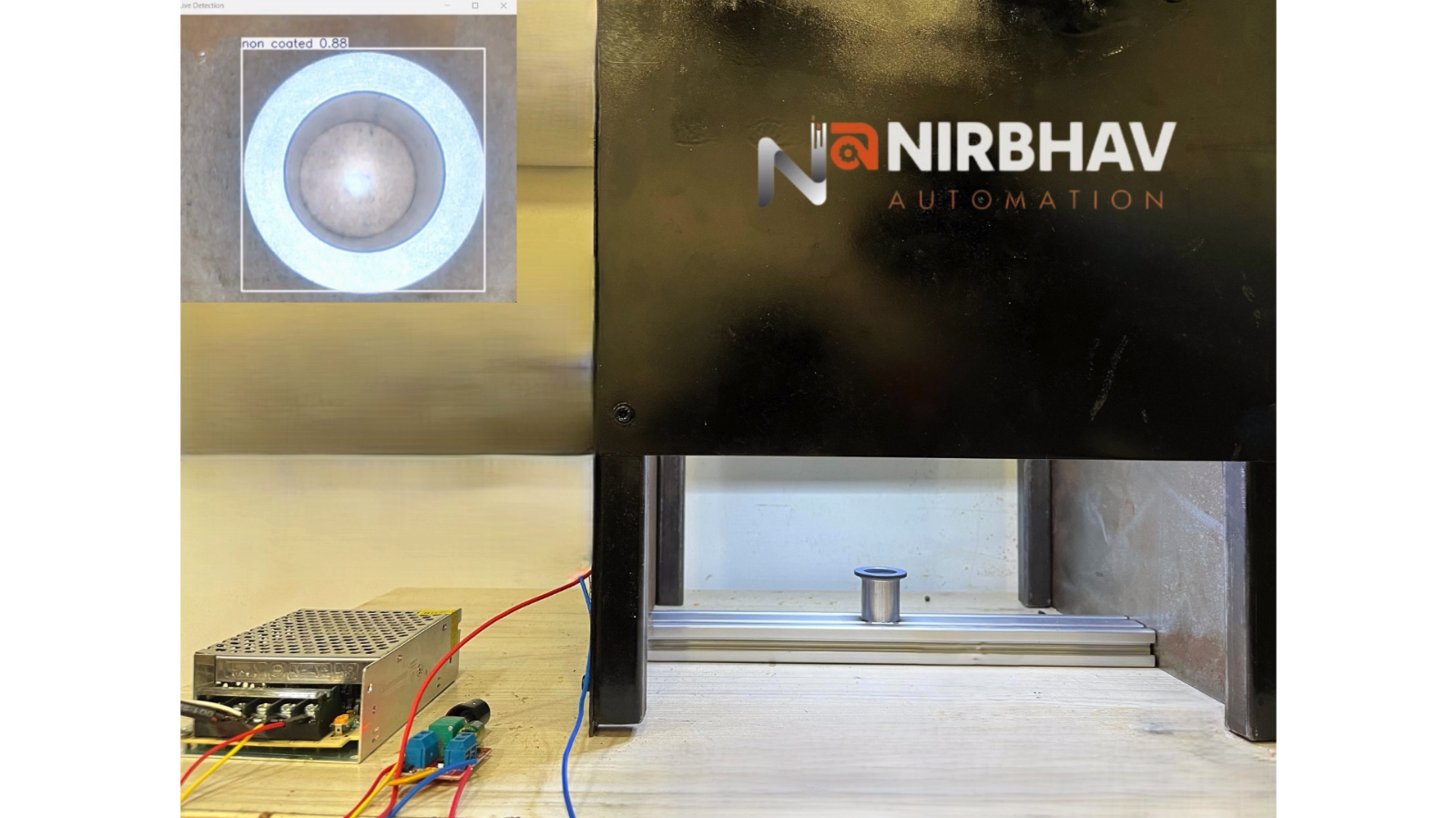

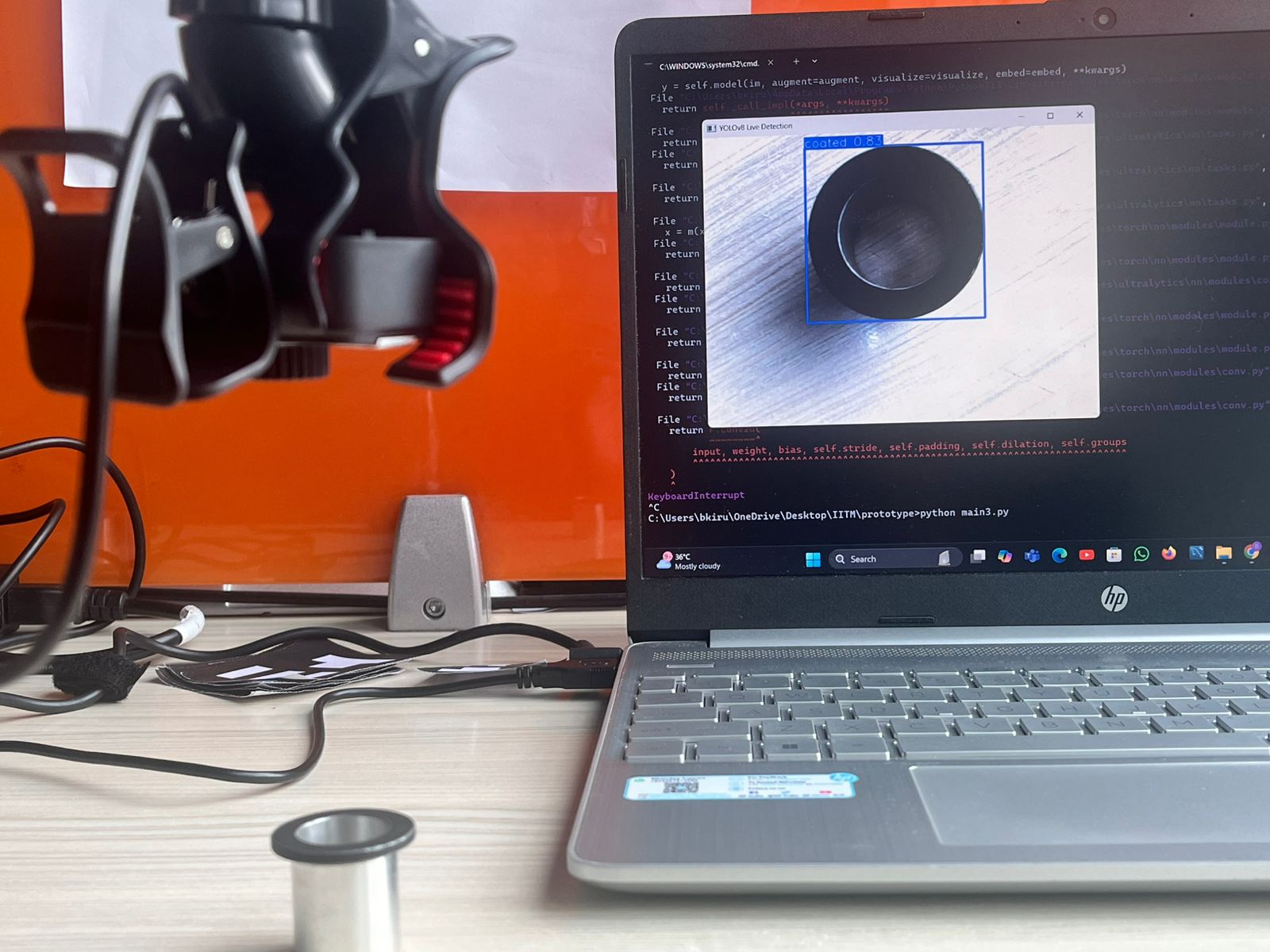

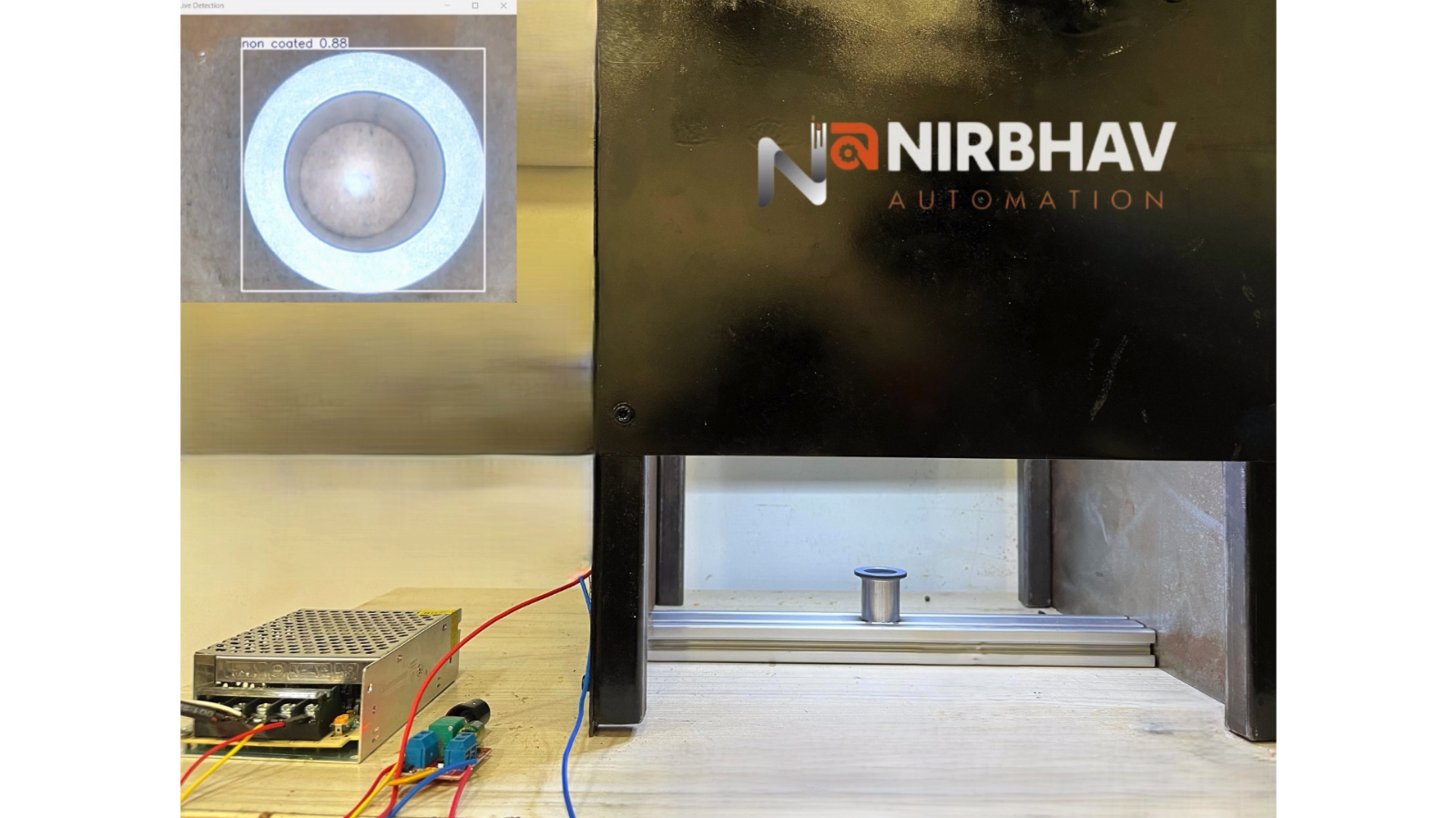

Our advanced AI-powered Machine Vision Inspection System for high-precision dimensional measurement and visual quality inspection of industrial components. The system integrates high-resolution cameras, precision optics and AI-driven analytics to enable automated, reliable inspection with high repeatability and accuracy. It performs dimensional analysis using AI algorithms to measure critical parameters like length, width, diameter and tolerances with micrometer precision, while also conducting coating inspections to assess coverage, detect surface defects, and estimate coating thickness through image analysis. With integrated edge processing and cloud-based analytics, it ensures real-time inspection, data logging and quality reporting.

This technology finds applications across industries in manufacturing and machining for dimensional checks and surface analysis in automotive and aerospace for critical part inspection and coating verification in metal processing for coating quality and defect detection in pharmaceutical and chemical packaging for defect and labeling checks and in electronics and PCB manufacturing for solder joint inspection and dimensional conformity.